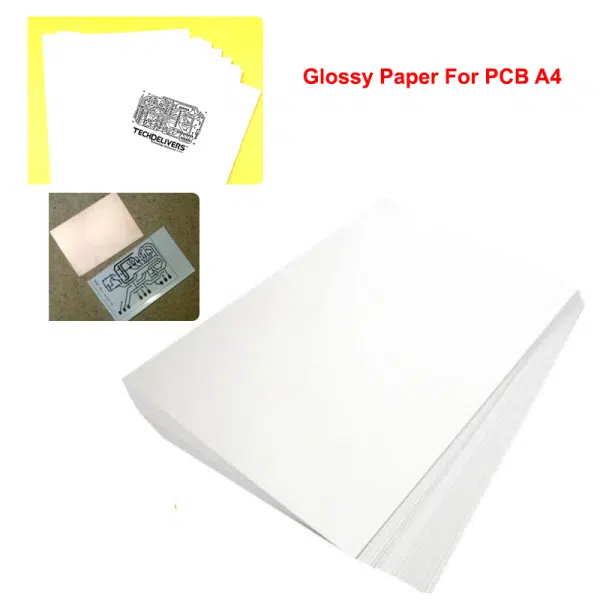

Thermal transfer method produced circuit boards in home easly , is to draw a good board graphics, laser printer to print in thermal transfer paper, then transfer paper covering the Bonded Copper heat, melt the toner is completely adsorbed in deposited copper, after cooling tear off the transfer paper, you can see the board graphics transfer to Bonded Copper, black anti-corrosion layer, that is, we want the PCB diagram, the final corrosion, that is, can get what we want the PCB.

You can only use the laser printer! Can not use an inkjet printer!PCB map with a laser printer, hit the smooth side and wrap it to the copper into fast plate-making machine or iron transfer to.

Heating tools used in the production process is iron (normal one that used at your hme) or laminator. We serve the transfer paper for the production of circuit boards for thermal transfer paper, with its production of circuit boards has the following advantages:

- High precision

- Low cost of plate.

- The speed of plate

- Can be used to make single or double sided PCB.

How to use:

- Use Laser printer to print circuit board circuit diagram to the shiny side of the thermal transfer paper.

- Raised to 150-180 degrees Celsius laminator, thermal transfer paper printed a schematic side deposited in Bonded Copper transfer; or you can use iron (normal one that used at your home) instead of a plate making machine, hand transfer.

- After printing remove the transfer paper, Bonded Copper into the ferric chloride solution corrosion.

- Finally, the toner of the gasoline to clean the circuit board.