Features

- Universal AC input range selectable by a switch

- Protections: short circuit and overload

- Cooling by free air convection

- LED indicator for power on

- 100% full load burn-in test

- Low cost and high reliability

Specification

| Model | ATO-S-100-5 | |

| Output |

DC Voltage | 5V |

| Rated Current | 20A | |

| Current Range | 0 ~ 20A | |

| Rated Power | 100W | |

| Ripple & Noise (Max.)(Note 2) | 100mVp-p | |

| Voltage Adjust Range | 4.75 ~ 5.5V | |

| Voltage Tolerance (Note 3) | ±2.0% | |

| Line Regulation | ±0.5% | |

| Load Regulation | ±0.5% | |

| Setup, Rise, Holdup Time | 200ms, 80ms, 20ms at full load | |

| Input | Voltage Range | 85 ~ 132VAC/180V~264VAC (selected by a switch) or 255 ~ 370VDC |

| Frequency Range | 47~63Hz | |

| Efficiency (Typ.) | 78% | |

| AC Current (Typ.) | 2.4A/115V AC 1.2A/230V AC | |

| Inrush Current (Typ.) | Cold start: 30A/115V AC 60A/230V AC | |

| Leakage Current | <1mA/240V AC | |

| Protection | Overload | 105~150% rated output power Protection type: Shut down output voltage, re-power on to recover. |

| Environment | Working Temperature | -10 ~ +60℃ |

| Working Humidity | 20~90% RH non-condensing | |

| Storage Temperature | -20~+85℃ | |

| Storage Humidity | 10~95% RH non-condensing | |

| Temperature Coefficient | ±0.03%/℃ (0~50℃) | |

| Vibration | 10 ~ 500Hz, 2G 10min./1 cycle, period for 60min. each along X, Y, Z axes | |

| Safety & EMC (Note 4) | Safety Standards | UL1012 Approved |

| Withstand Voltage | I/P-O/P: 1.5KVAC I/P-FG: 1.5KVAC O/P-FG: 0.5KVAC | |

| Isolation Resistance | I/P-O/P, I/P-FG, O/P-FG: 100M Ohms/500VDC/25℃/70% RH | |

| EMC Emission | Compliance to FCC Part 15 J conduction Class B | |

| Others | MTBF | ≥322.4K hrs MIN. MIL-HDBK-217F (25℃) |

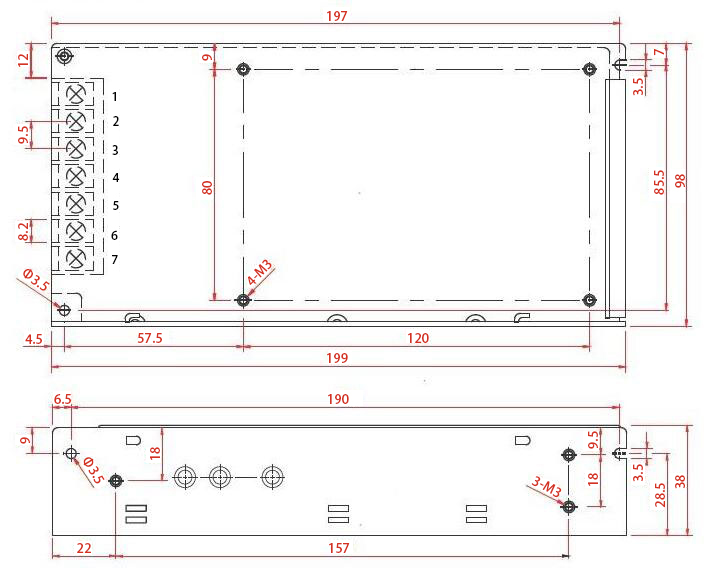

| Dimension | 199*98*38mm (L*W*H) | |

| Weight | 0.63kg | |

| Note | 1. All parameters NOT specially mentioned are measured at 230V AC input, rated load and 25°C of ambient temperature. 2. Ripple & noise are measured at 20MHz of bandwidth by using a 12″ twisted pair-wire terminated with a 0.1uf & 47uf parallel capacitor. 3. Tolerance includes set up tolerance, line regulation and load regulation. 4. The switching power supply is considered a component which will be installed into final equipment. Please make sure that the final equipment still meets EMC directives. |

|

Dimension (Unit: mm)

SMPS Power Supply Applications

- Power Tools

Electric Saw, Drilling Machine, Ginder, Sand Blast Machine, Puching Machine, Weeding Machine, Air Compressor, etc. - Offices Devices

Computer, Printer, LCD Monitor, Scanning Machine, etc. - Electrics & Household Appliance

TV, VCRS, Radio, Dust Collector, Fan Lamp or LED Strip, Sewing Machine, Microwave Oven, Fridge/Freezr, Coffemarker, etc. - Industrial Equipemnt

Monitoring Equipment, Shipping, Vehicle, Metalhalide Lamp, Solar System, Wind Power Generation, etc.

Tips: Working principles of switching power supply

In simple words, switching power supply operates by the following working principles:

- AC is rectified and smoothed to DC.

- Output the DC to primary level of switch transformer by high-frequency signal control switch.

- Primary level of the switching transformer detects high-frequency voltage and supply the voltage to load through rectification and smoothing process.

- The output system sends feedbacks to the control circuit through certain circuits to regulate current output by controlling occupation ratio of PWM.

AC needs to go through the choking coil when being input. Switching power supply is used to filter noise wave of power grid and prevent power supply from outputting noise waves to the power grid. If the power stays the same, higher frequency of the switch will indicate smaller size of switch transformer and higher requirement for switch tube. To meet requirements for output, secondary level of the switch transformer is composed of several windings or just one winding with several taps. Generally speaking, the switch transformer is often equipped with protective circuit to protect switching power supply from idle load or short circuit, or the power supply may be burned out.