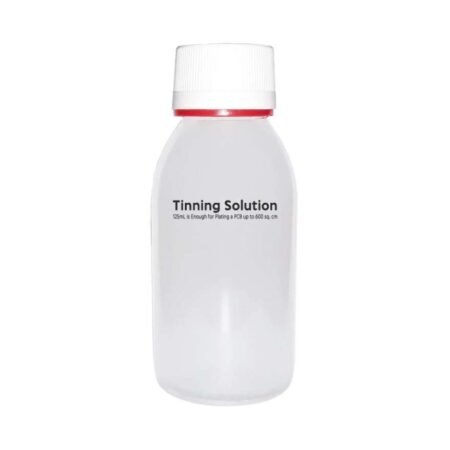

The solution is suitable for plating the copper tracks in electronic circuits by immersion without electricity (Electroless), as a very thin layer of tin is deposited on it in a short time at room temperature, to improve the quality of PCBs used in industry-making engineering projects, tech prototypes for students, technicians, and specialist engineers in the field of electricity and electronics, as well as hobbyists.

The solution is safe and suitable for use in the laboratory or at home, by following simple tech steps for tinning one or more PCBs so it saves time and cost.

Features:

• Protect PCB from Corrosion.

• Increase The Durability of The PCB Tracks and Their afford to Electric Current.

• Improve the Quality of Tin Soldering for PCB.

• PCB Tracks Active and Bright.

• Electroless Very Easy Plating.

• Non-Toxic.

• Very Safe When Handling, Using and After Plating.

• 125mL is Enough for Plating a PCB up to 600 sq. cm in Less than 25 Seconds at a temperature of (20 to 30 Celsius).

Usage:

• Manufacturing of Electrical & Electronic PCB.

• PCB Solder Mask.

For Using:

1. Preparing a Suitable Plastic Container for PCB Size.

2. Clean PCB with a Soft Steel Wool Grade 0000 (The Copper Should Be Quite Shiny and Oxide Free).

3. Rinse with Warm Water (Don’t Touch PCB Copper Tracks).

4. Put PCB in the Container (The Copper Tracks is Up).

5. Shake the Solution Bottle, Pour the Solution until the PCB is Fully Covered, and Wait for 25 Sec Max.

6. Rinse PCB with Water After Plating.

7. Dry PCB.

Notice:

• The Solution Temperature is Recommended to be from 20 to 30 Celsius.

• Keep the Bottle Tightly Closed After Use to Preserve the Solution from Oxidation.

• Discard the used solution and do not refill it again in the Bottle.

Safety Precautions:

• Wearing Plastic Gloves is Recommended When Using.

• Close After Using and Keep Away from Children.

• Use Enough Water When Eyes or Wounds Are Touched.

Appearance:

The Solution is a Very Light-White Liquid, Packaged in a Transparent Plastic Bottle with a capacity of 125mL.