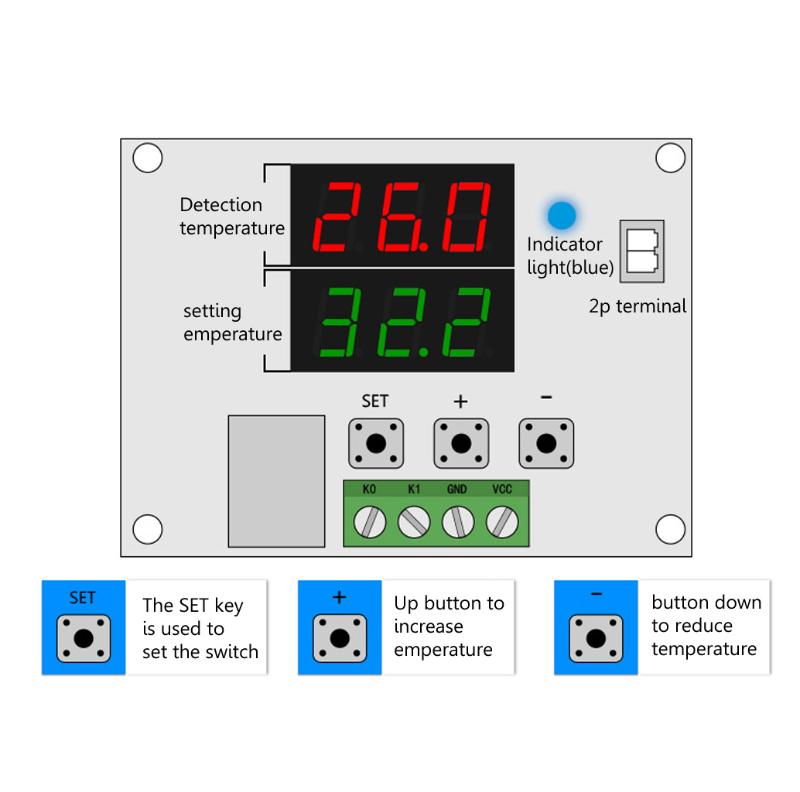

XH-W1219 Dual LED Display Thermostat Temperature Controller Module

This is an XH-W1219 digital thermostat controller module that controls the temperature by first, calculating the temperature (process variable), and then comparing it to the desired value (set value). The difference between these values is known as the error (deviation).

Temperature controllers use this error to decide how much heating or cooling is required to bring the process temperature back to the desired value. Once this calculation is complete the controller will produce an output signal that affects the change required. This output signal is known as the (manipulated value) and is normally connected to a heater, control valve, fan, or some other “final control element” that injects or removes heat from the process. This can be in a situation where an object is required to be heated, cooled, or both and to remain at the target temperature (set point), regardless of the changing environment around it. There are two fundamental types of temperature control; open-loop and closed-loop control. Open-loop is the most basic form and applies continuous heating/cooling with no regard for the actual temperature output.

Closed-loop control is far more sophisticated than open-loop. In a closed-loop application, the output temperature is constantly measured and adjusted to maintain a constant output at the desired temperature. Closed-loop control is always conscious of the output signal and will feed this back into the control process. Temperature controllers in the industry work much the same way they do in common household applications.

A basic temperature controller provides control of industrial or laboratory heating and cooling processes.

Specifications:

- Model: XH-W1219

- Power Supply: DC12V

- Relay Current: 50mA

- Control Range: -50~110 Celsius

- Control Precision: 0.1 celsius

- Measuring Input: NTC10K waterproof sensor L=0.5m

- High Temperature Alarm: -49~110 celsius

- Input Voltage: DC 12V

- Output Type: relay output 10A (max)

- Return Difference Setting: 0.1~30 celsius

- Delay Starting: 0-10min

- Temperature Calibration: -10~10 Celsius

- Size: 60 x 44 x 16mm

How to restore factory settings:

- PO temperature control mode: This value must be set when the thermostat is used for the first time. If it is used for heating, it must be set to H. If it is used for cooling, it should be set to C.

- P1 difference setting: Press the SET button for a long time to enter the internal settings, select the P1 setting, and then press the SET button again to set the hysteresis value. (The hysteresis is the difference needed when the thermostat reaches the set temperature and stops working again.)

- P2 temperature calibration: This function is used for temperature calibration. If there is a deviation between the detected temperature and the actual temperature, this function can be used to correct. The corrected value = measured value + correction value. (If you do not control the compressor or do not need the delay function, skip this item directly)

- P4 high-temperature alarm: Set the high-temperature alarm value. When the real-time temperature exceeds this value, the screen will flash a warning alarm.